EVA, an acronym for Ethylene Vinyl Acetate, is a versatile material that holds great significance in various industries. Its unique characteristics and properties make it a sought-after material choice for applications ranging from footwear to automotive components. In this article, we will delve into the world of EVA, exploring its definition, composition, and diverse applications.

What is EVA?

EVA, which stands for Ethylene Vinyl Acetate, is a versatile and popular material used in various industries. In this chapter, we will delve into the characteristics, composition, manufacturing process, and properties of EVA, with a particular focus on EVA foam.

What is EVA Material?

EVA is a copolymer thermoplastic material. It is created by combining ethylene and vinyl acetate monomers, which undergo a polymerization process. EVA material is known for its flexibility, impact resistance, and ability to withstand harsh environmental conditions. These properties make it a desirable material in a wide range of applications.

What is EVA Made Of?

EVA is primarily composed of two main components: ethylene and vinyl acetate. Ethylene is a hydrocarbon gas derived from petroleum, while vinyl acetate is a chemical compound synthesized from acetic acid. The ratio of ethylene to vinyl acetate content can vary, resulting in EVA with differing properties and characteristics.

How EVA is Made?

The production of EVA involves a polymerization process. First, ethylene and vinyl acetate monomers are combined in a reactor. This mixture is then subject to high heat and pressure, initiating a chemical reaction known as copolymerization. As a result, the ethylene and vinyl acetate molecules join together to form long chains, creating the EVA polymer. Various catalysts and additives may be used to control the reaction and enhance specific properties of the resulting EVA.

What is EVA Foam?

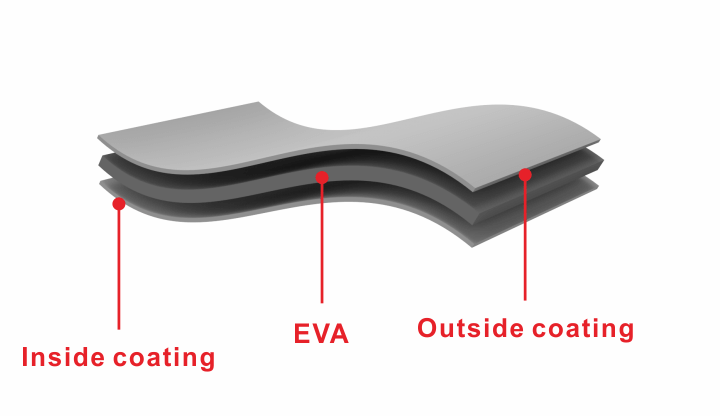

EVA foam is a type of expanded cellular material derived from EVA. It is created through a foaming process that involves introducing gas or blowing agents to the EVA polymer during its production. This generates small gas bubbles within the material, resulting in a spongy and lightweight foam structure. EVA foam exhibits excellent cushioning, shock absorption, flexibility, and thermal insulation properties, making it suitable for various applications, including footwear, sports equipment, packaging, and more.

Characteristics of EVA Material

Flexibility and Resilience

One of the key reasons for EVA’s popularity is its remarkable flexibility and resilience. It can withstand repeated stress without losing its shape or integrity, making it ideal for applications that require durability, such as footwear and sports equipment.

Water and Weather Resistance

EVA exhibits excellent resistance to water and weather, making it suitable for outdoor applications. Its closed-cell structure prevents moisture absorption, ensuring that it remains unaffected by wet conditions. This property further enhances its durability and longevity.

Lightweight and Buoyant Nature

EVA is known for its lightweight and buoyant nature. This quality makes it an ideal choice for footwear and sporting equipment, as it provides excellent cushioning and shock absorption while minimizing the overall weight of the product.

What is EVA Used for?

EVA in the Footwear Industry

source: pinterest

The footwear industry has witnessed a significant transformation with the introduction of EVA. Its foam soles and insoles have revolutionized the comfort and performance of shoes. Due to its lightweight and cushioning properties, EVA foam is used extensively in creating comfortable and supportive shoe soles, providing enhanced shock absorption and preventing foot fatigue. EVA is also a popular material for manufacturing sandals and flip-flops, particularly for leisure and beachwear, as it offers a combination of comfort, water resistance, and durability.

EVA on Sports and Fitness Equipment

source: pinterest

EVA’s distinctive characteristics make it an essential component in the sports and fitness equipment industry. With its exceptional shock-absorbing properties, EVA plays a critical role in ensuring the safety of athletes and fitness enthusiasts. It is commonly used as padding for helmets and protective gear, significantly reducing the risk of injury during intense physical activities. Additionally, EVA yoga mats and exercise blocks have gained immense popularity due to their superior cushioning, grip, and stability, allowing individuals to engage in yoga and other exercises comfortably and safely.

EVA in the Packaging Industry

The packaging industry greatly benefits from the versatility and protective qualities of EVA. EVA cases are widely utilized to safeguard digital devices and small electrical appliances from potential damage during transportation. The resilience and cushioning properties of EVA foam inserts make them an ideal choice for delicate and electronic products, offering reliable protection against impact and shocks. Furthermore, EVA foam sheets are commonly used for cushioning and safeguarding goods during shipping, preventing breakage and ensuring product integrity.

EVA in the Automotive Sector

source: pinterest

EVA’s applications extend to the automotive sector, where its unique properties serve practical purposes. EVA car mats, known for their durability and easy cleaning, provide an efficient solution to maintain cleanliness and protect the car’s interior flooring. Additionally, EVA seals and gaskets play a crucial role in noise reduction and insulation within vehicles, improving overall comfort and reducing unwanted sounds from permeating the cabin.

EVA vs. PVC

What is PVC (Polyvinyl Chloride)?

source: pinterest

Polyvinyl Chloride, commonly known as PVC, is a widely used synthetic material. It is produced by the polymerization of vinyl chloride monomers. PVC has been popular for many years due to its low cost and versatility in various applications.

Advantages of EVA over PVC

While PVC has its merits, EVA possesses distinct advantages that set it apart as a preferred material choice.

- EVA’s flexibility and ease of processing

EVA offers greater flexibility compared to PVC, enabling it to be easily shaped and molded into various forms. Its low melting point allows for effortless processing, making it a preferred material for manufacturers.

- EVA’s superior weather resistance and color stability

In terms of weather resistance, EVA outperforms PVC. It has exceptional resistance to ultraviolet (UV) radiation, preventing color fading and degradation over time. This property makes it especially suitable for outdoor applications where exposure to sunlight is inevitable.

- EVA’s lower environmental impact compared to PVC

EVA is considered to have a lower environmental impact than PVC. It is a more environmentally friendly choice due to its composition and production process. EVA does not release harmful substances during its lifecycle, making it a viable option for industries focused on sustainability.

Instances where PVC may be a More Suitable Choice

While EVA possesses numerous advantages, PVC may still be the more suitable choice for specific applications. PVC’s inherent rigidity and chemical resistance make it ideal for applications requiring these specific characteristics. For example, PVC pipes and fittings are widely used in plumbing systems due to their ability to withstand chemical corrosion and maintain structural integrity.

Conclusion

In conclusion, EVA is a remarkable material with a wide range of applications across various industries. Its origins in the manufacturing sector paved the way for its widespread usage today. The versatility and unique characteristics of EVA, such as flexibility, resilience, water resistance, and lightweight nature, have made it a preferred choice in industries such as footwear, sports equipment, packaging, and automotive. While PVC remains a viable option for certain applications, EVA’s advantages, including its ease of processing, superior weather resistance, and lower environmental impact, position it as a material with immense potential for innovation and future growth.