Eva foam stands as a versatile material that has found its place in various industries due to its exceptional properties. From the automotive and sports industry to arts and crafts and packaging, Eva foam has proved its worth and importance. In this blog post, we will delve into the world of Eva foam, exploring its definition, uses, manufacturing process, different types, and how it compares to other materials. By the end of this article, you will have a comprehensive understanding of Eva foam and its potential applications.

What is Eva Foam?

Eva foam, also known as ethylene-vinyl acetate foam, is a closed-cell foam made from a copolymer of ethylene and vinyl acetate. It is a highly versatile material that offers a wide range of benefits due to its unique properties. Eva foam is lightweight, flexible, and shock-absorbent, making it an ideal choice for numerous applications. Moreover, it is odorless, non-toxic, and resistant to water, UV rays, chemicals, and weathering. These qualities contribute to its popularity and extensive use in various industries.

Pros and Cons of Eva Foam

source: pinterest

Eva Foam The pros of Eva foam are numerous and worth considering. Firstly, its lightweight nature makes it easy to handle and transport, while also providing comfort and ease of use in applications such as footwear. Secondly, Eva foam exhibits excellent cushioning and shock absorption properties, making it perfect for protecting delicate products or providing support in sporting equipment. Additionally, Eva foam is highly resistant to water, UV rays, chemicals, and weathering, ensuring durability and longevity. On the other hand, one potential drawback of Eva foam is its susceptibility to compression over time, which may affect its cushioning ability in certain applications. However, with proper care and maintenance, this issue can be mitigated.

Pros of Eva Foam

- Lightweight and flexible

- Excellent shock absorption

- Water and chemical resistant

- UV resistant

- Versatile

Cons of Eva Foam

- Susceptible to compression over time

- Limited temperature range

- Not fireproof

- Limited load-bearing capacity

- Environmental impact

What is Eva Foam Used For?

Eva foam is an incredibly versatile material that finds applications in various industries. Here are some of the common uses of Eva foam:

Automotive Industry

source: pinterest

source: pinterest

Eva foam is commonly used in the automotive industry for interior components such as car mats, seat cushions, and door panels. Its durability and resistance to wear and tear make it an ideal choice for these applications.

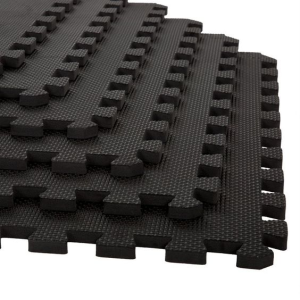

Sports Industry

source: pinterest

Eva foam plays a crucial role in the sports industry, where it is used in the production of protective gear, footwear, and exercise mats. Its cushioning and shock absorption properties enhance safety and comfort during sports activities.

Packaging Industry

Eva foam is widely used as a protective packaging material and used in eva case such as Eva camera case, Eva medical equipment case and so on. Its lightweight and shock-absorbent nature make it perfect for safeguarding delicate and fragile items during transit.

Arts and Crafts Industry

source: pinterest

Eva foam is a popular choice in the arts and crafts industry due to its malleability and ease of handling. It is commonly used for creating costumes, props, cosplay and decorations.

How is Eva Foam Made?

The manufacturing process of Eva foam involves several steps that result in the production of a versatile and high-quality material. It begins with the selection of raw materials, which include ethylene-vinyl acetate copolymer, foaming agents, and additives. The foam molding or extrusion process follows, where the raw materials are melted and mixed together, and then pumped through an extruder, forming a continuous sheet of foam. This eva foam sheet is then cooled and cut into the desired shape and size. The density of the foam can be adjusted during the manufacturing process by controlling the amount of foaming agent and the speed of the extrusion process. Additional treatments or enhancements can be applied to the Eva foam, such as anti-static properties or flame retardancy, depending on the specific application requirements.

Types of Eva Foam

source: pinterest

Eva foam is available in a variety of types, each offering unique characteristics and benefits. Here are some of the common types of Eva foam:

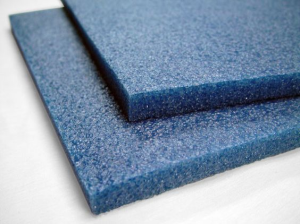

Low-Density and High-Density Eva Foam

Eva foam is classified into low-density and high-density categories. Low-density foam is softer and more flexible, making it suitable for cushioning and comfort applications. High-density foam, on the other hand, is more rigid and durable, providing excellent support and protection.

Colors, Thicknesses, and Finishes

Eva foam comes in different colors, allowing for customization and aesthetic appeal. It is also available in various thicknesses and finishes, catering to specific project requirements.

Anti-Static or Flame-Retardant Eva Foam

In certain industries, such as electronics or fire safety, special types of Eva foam are required. Anti-static Eva foam helps in preventing electrostatic discharge, while flame-retardant Eva foam offers enhanced fire resistance.

Specialty Eva Foam Options

Additionally, there are specialty options for Eva foam, such as extra soft or extra firm foam, which cater to niche applications and unique projects.

Eva Foam vs Other Materials

When it comes to comparing Eva foam with other materials, several factors come into play, such as their specific properties, advantages, and disadvantages. Let’s explore some common comparisons:

PE Foam vs Eva Foam

source: pinterest

Both PE foam (polyethylene foam) and Eva foam share some similar properties, such as being lightweight, water-resistant, and shock-absorbent. However, Eva foam offers better flexibility and cushioning capabilities, making it more suitable for comfort-driven applications.

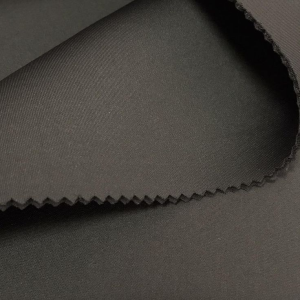

Neoprene vs Eva Foam

source: pinterest

Neoprene is a synthetic rubber material known for its excellent resistance to water, chemicals, and weathering. While sharing some similarities, Eva foam surpasses neoprene in terms of shock absorption, flexibility, and customization options. Therefore, it is often the go-to choice for applications requiring cushioning and comfort.

Eva Foam vs PVC Foam

source: pinterest

Eva foam and PVC foam are both popular choices for various applications. Eva foam, however, has a significant advantage when it comes to being environmentally friendly. PVC foam, on the other hand, offers better resistance to oils and chemicals, making it suitable for applications in the industrial sector.

Choosing the Right Eva Foam

Selecting the appropriate Eva foam for a specific application involves considering various factors to ensure optimal performance and functionality.

Firstly, the density of the foam should be chosen based on the desired level of support or cushioning required. Low-density foam is ideal for comfort purposes, while high-density foam provides better structural integrity and protection.

Secondly, the desired thickness and firmness should be evaluated according to the specific application requirements. Thicker foam may be necessary for applications that require more impact resistance, while a firmer foam may be preferred for applications requiring greater support. Additionally, it is important to consider the desired color and finish of the foam, as they can enhance the aesthetic appeal and suitability for specific projects.

Finally, certain industries or uses may require special considerations, such as anti-static or flame-retardant properties, which should be taken into account during the selection process.

Maintenance and Care of EVA Foam Products

To ensure the longevity and performance of Eva foam products, proper maintenance and care are essential. Cleaning the foam regularly with mild soap and water can help remove dirt and stains. Avoid using harsh chemicals or abrasive materials that may damage the foam’s surface. In cases of heavy staining, spot cleaning with appropriate cleaning products or seeking professional cleaning services may be necessary. Additionally, it is recommended to store Eva foam products in a cool and dry place, away from direct sunlight, to prevent any degradation or discoloration over time. By following these simple maintenance practices, the lifespan and functionality of Eva foam products can be maximized.

Conclusion

Eva foam is a versatile material with exceptional properties that make it suitable for various industries. Its lightweight, flexible, and shock-absorbent nature offers numerous advantages. From automotive and sports to arts and crafts, Eva foam finds applications in a wide range of sectors. With its vast potential and advantages, Eva foam opens up endless possibilities for creativity and innovation. Embracing the versatility of Eva foam can lead to exciting projects and success. We encourage readers to share their experiences and creations with Eva foam, paving the way for new and exciting possibilities.